Testing Phase 1 – Independent Laboratory

Testing Phase 2 – Tester Panel

Spezielle Bestellanweisungen

Pferdebekleidung

Pferdebekleidung

Therapie

Pferdestiefel

Sonne & Flug

Halfter & Führstricke

Teppiche

Reitzubehör

Ernährung

Ernährung

Futter- und Heublöcke

Leckereien

Haynets

Bucket Covers

Shop by Pet

Reichweite

Additional B2B Information

Additional B2B Information

Disziplin

Bildungszone

As riders, we protect our most vital areas (head and torso) with riding hats, body protectors and more recently air jackets. Rider protective equipment is subjected to extensive testing to meet standards and regulations and we believe that as a vital part of your horse, protective boots for your horse’s legs should undergo a similar testing process.

Tri-Zone boots go through a unique 3-phase testing process, giving you confidence that you are choosing the best leg protection for your horse. Materials are carefully selected to provide maximum protection but without being bulky, heavy and not make your horses legs hot and sweaty. Each individual layer in the Tri-Zone boot is researched and sourced for their advanced technical properties and tested in an independent laboratory before it goes anywhere near a horse’s leg.

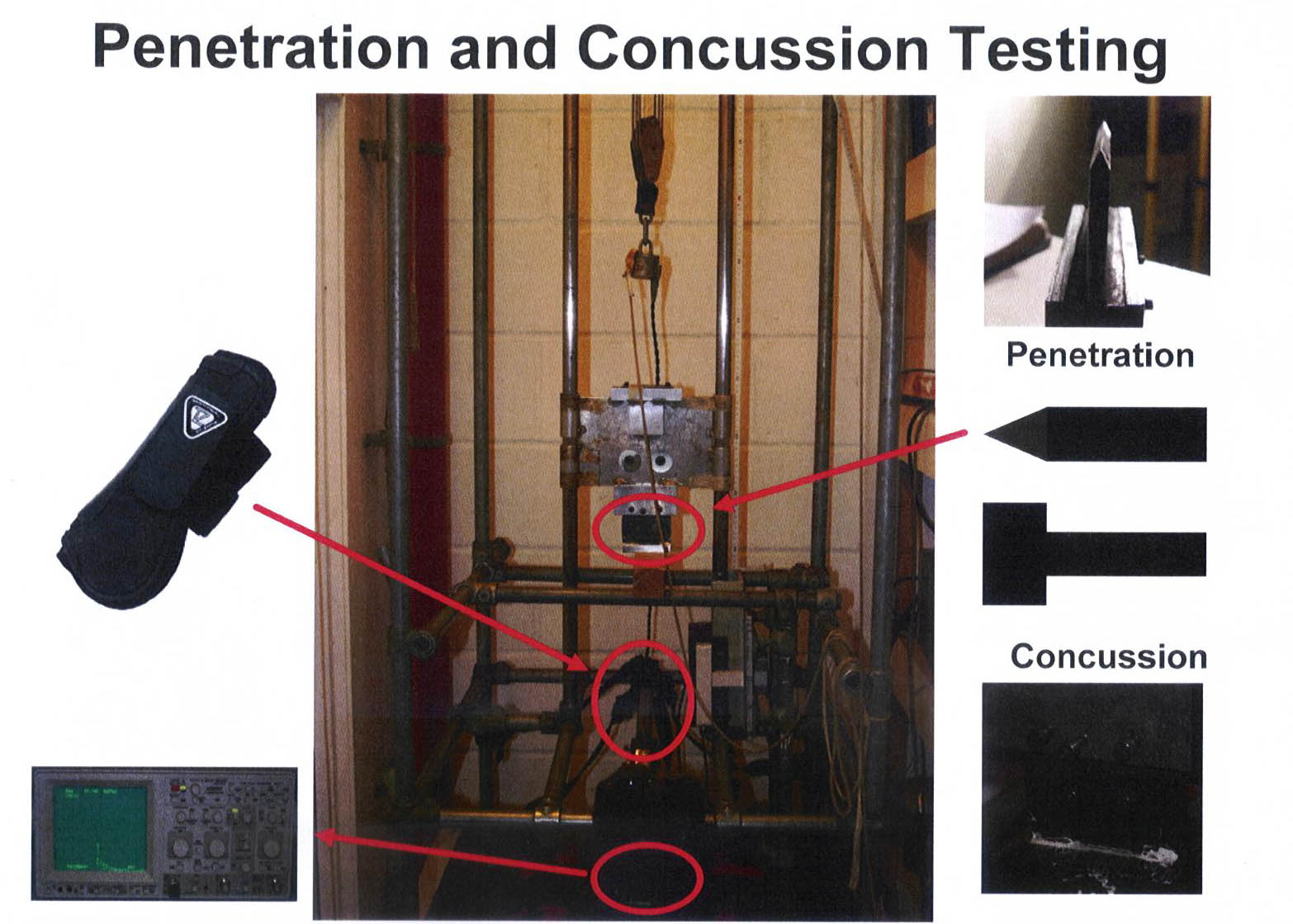

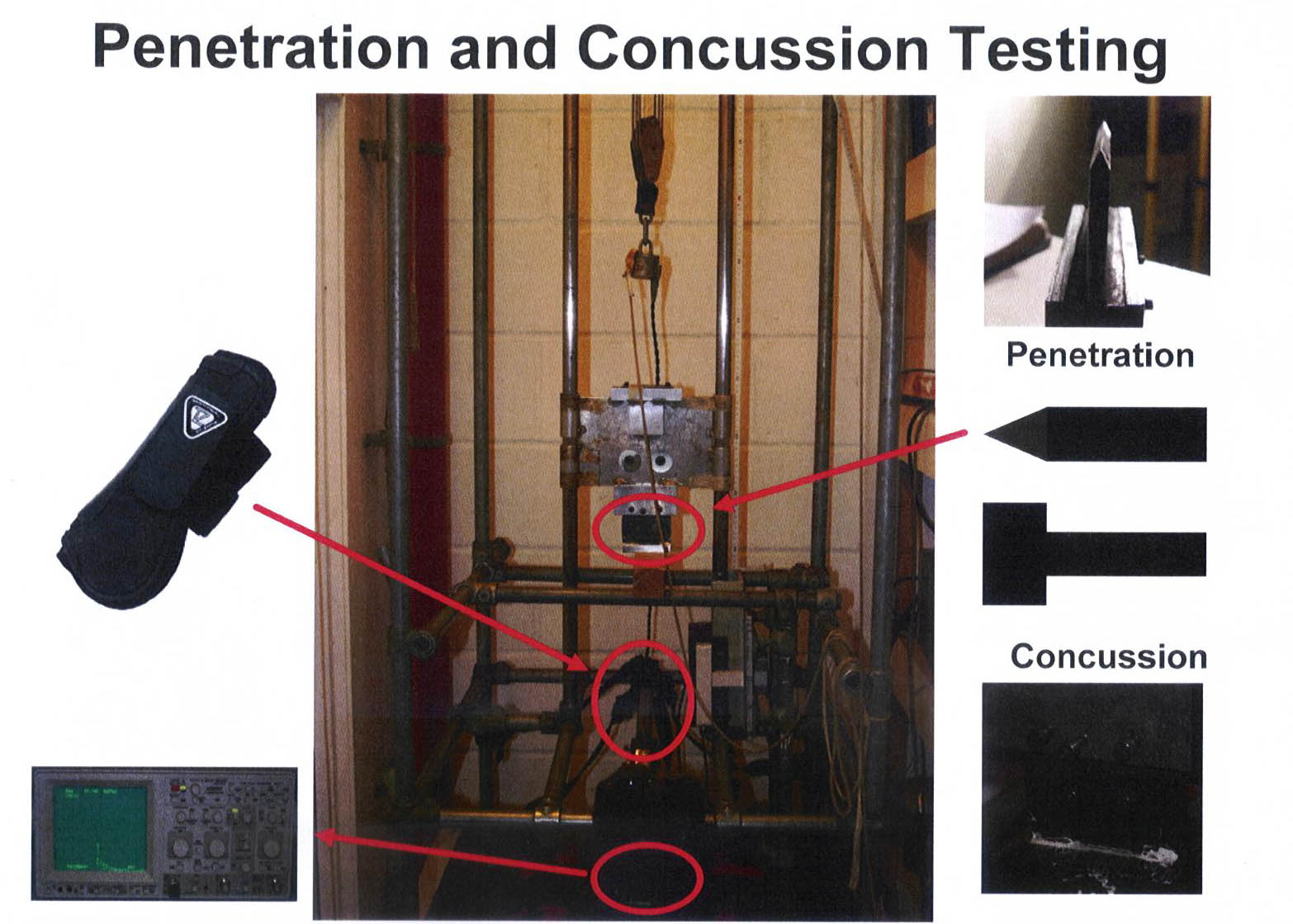

In the same laboratory that test standards of riding hats and body protectors, Tri-Zone boots are safety tested to their limits for their ability to withstand concussion and penetration whilst remaining lightweight, breathable and flexible.

For concussion and penetration the testing is carried out using a custom made test rig consisting of a tower from which either a blunt hammer or a cutting blade is dropped onto the boots in a controlled fashion. The weight of the blade and hammer are fixed and different forces are applied to the boots by varying the height from which they were dropped onto the boots. Boots were hit with forces ranging from 1.25 to 20 Joules. These forces were chosen as being those likely to occur in the horse during exercise, for example when hitting obstacles or over-reaching.

We test our boots to measure how well the boots allow heat to escape in order to reduce the risk of tissue damage.

Research has shown that when tendon cells are heated to 48°C for 10 minutes approx, 80% of them die*. We use several different methods to assess heat release from boots. The heat release is estimated by fitting the boots to a metal flask containing water at 45°C in a room at 20°C with no significant radiation. The surface temperature of the boots is measured using a thermal camera. We tested Tri-Zone boots, along with a number of other boots on the market.

From this it was clear that some boots were very effective insulators and kept the heat in so the outside of the boot appeared cold. Other boots appeared much hotter on the surface, showing that they were allowing heat to escape.

Heat release was then estimated by measuring the rate at which the temperature of the water in the flask dropped whilst 20°C air was being blown over the boot (via a fan). This was done to simulate the movement of air over the boot and leg as would occur during exercise.

If boots are constructed of inflexible (i.e. stiff) material or if boots are applied too tightly, they have the potential to restrict joint movement and cause other problems such as tendonitis. Stride characteristics and performance could also be affected. Boots need to allow as much freedom of movement as possible without compromising on their primary function of protection. We test our boots to make sure that they do not restrict the horse’s movement whilst still exceeding protection requirements. An 8cm x 1m steel pipe is set up secured to a workbench. The boots are fixed to the pipe and a 10kg weight is attached with a clip on the boot and the downward direction measured. The degree of flexibility is measured by how much the boot bends.

Adding even small amounts of weight to the end of the leg in the form of a boot significantly increases the effort the horse must make to run and can also alter the stride characteristics. Some boots can double in weight if the horse is being exercised in the rain, on wet ground or going through water. This can seriously affect stamina and performance. We design and test our boots to minimise water absorption, excess weight but without compromising on protection.

The boots then undergo trials by an extensive tester panel of horse owners and riders who test them for the fit, comfort, ease of use and washing to ensure we have not only a safe product but one that people can easily use and trust.

Finally the boots go through the rigorous test of being used all day, every day on busy competition yards by teams of professional riders. Tri-Zone boots are worn either at home or at competitions by an array of Olympic riders, world champions and top producers.

Ein Leitfaden für Pferdegamaschen, Bandagen und Chaps

Als Reiter und Pferdebesitzer verlangen wir von unseren Pferden, dass sie auf eine Art und Weise leben und arbeiten, die sie in der freien Natur nicht tun würden. Daher müssen wir ihre Beine vor Verletzungen durch äußere Einflüsse, selbst zugefügte Verletzungen und stressbedingte Probleme schützen.

Tri-Zone-Stiefel-Atmungsaktivitätstest

Die Tri-Zone Brushing Boots wurden unabhängigen Tests mit Dr. David Marlin unterzogen, um genau festzustellen, wie atmungsaktiv sie sind und wie sie im Vergleich zu anderen ähnlichen Stiefeln auf dem Markt abschneiden. Die Testmethode wurde entwickelt, um die Menge an Feuchtigkeit zu messen, die aus dem Stiefel entweicht. Dies wurde in einer kontrollierten Laborumgebung durchgeführt, um so viele Variablen wie möglich auszuschließen, die bei Tests an einem lebenden Pferd auftreten können.

Die Wahl des richtigen Tri-Zone-Gamaschen für Ihr Pferd

Die Tri-Zone-Reihe wird unabhängigen Tests unterzogen, um sicherzustellen, dass jeder Stiefel seiner jeweiligen Aufgabe gewachsen ist – egal, ob es sich um einen Bürstenstiefel oder einen Stiefel für hohe Belastungen handelt. Unabhängig vom Schutzniveau wird jedes Stiefeldesign optimiert, um sicherzustellen, dass es so atmungsaktiv, leicht und flexibel wie möglich bleibt, um Bewegungsfreiheit und Komfort für Ihr Pferd zu gewährleisten.

Melden Sie sich für unsere Mailingliste an, um Updates zu unseren Produkten, Verkäufen und exklusiven Prämien zu erhalten

Verbinde dich mit uns

© 2026,

Equilibrium.Copyright © 2024 Equilibrium Products Limited. Eingetragen in England und Wales Nr. 03762996.

Wir verwenden Cookies und ähnliche Technologien, um die bestmögliche Erfahrung auf unserer Website zu bieten.